Agitated Thin Film Evaporators (ATFE)

Your Trusted Partner in Advanced Evaporation Solutions – Acmefil Engineering System Pvt. Ltd.

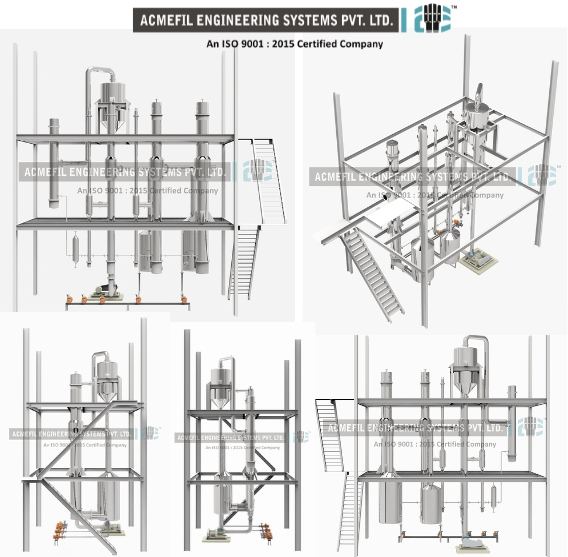

Welcome to Acmefil Engineering System Pvt. Ltd., a leading manufacturer of advanced Agitated Thin Film Evaporator (ATFE) technology. Our efficient, reliable solutions are engineered to handle heat-sensitive and viscous products with ease. Discover how our innovative systems enhance thermal processing, maintain product quality, and reduce operational costs—all backed by our expertise and commitment to sustainability.

Tailored Solutions

Custom designs and turnkey plant solutions for your needs.

Proven Expertise

Over 800 successful installations across industries.

Certified Quality

ISO 9001:2015 certified for highest industry standards.

Who we are?

Acmefil Engineering Systems Pvt Ltd

we specialize in designing and manufacturing state-of-the-art agitated thin film evaporators (ATFE) that cater to a wide range of industrial applications. Our commitment to innovation, quality, and customer satisfaction has positioned us as a leading provider of evaporation solutions globally.

Custom Engineering

Quality Manufacturing

About Agitated Thin Film Evaporators

What is an Agitated Thin Film Evaporator (ATFE)?

An Agitated Thin Film Evaporator (ATFE) is a specialized device designed to evaporate, concentrate, or distill liquids while maintaining product integrity. Its core principle lies in spreading the liquid into a uniform thin film across a heated surface, facilitated by a rotating agitator. This setup significantly reduces residence time, minimizing thermal decomposition and degradation of sensitive materials. ATFE systems excel in handling viscous fluids, slurries, and products prone to fouling, making them indispensable in industries such as pharmaceuticals, chemicals, nutraceuticals, and food processing. By combining mechanical agitation with advanced heat transfer, ATFEs deliver high evaporation rates in a compact footprint.

How ATFE Works:

- Feed Introduction: The liquid or slurry enters the top of the ATFE, where it immediately encounters the rotating agitator.

- Thin Film Formation: The agitator’s rotating blades spread the feed into a thin, uniform layer over the interior surface of the evaporator.

- Heat Transfer: A heating medium (commonly steam or hot oil) circulates through the jacketed cylinder or through a shell-and-tube arrangement. This continuous heat input allows rapid evaporation of the volatile components.

- Vapor Removal: As the volatile components evaporate, they are drawn into a vapor separator or overhead condenser, ensuring minimal entrainment and optimal separation.

- Concentrate Discharge: The concentrated liquid or residue collects at the bottom and is drained out through a dedicated outlet, ready for further processing or disposal.

Applications and Industries

Where Can ATFE Be Applied?

Agitated Thin Film Evaporators find widespread use across multiple sectors where precise thermal processing is critical:

- Pharmaceuticals: Ideal for gentle concentration of active pharmaceutical ingredients (APIs), intermediates, and sensitive compounds.

- Chemicals: Perfect for handling corrosive, viscous, or heat-labile chemicals, including specialty and fine chemicals.

- Food & Beverages: Used for concentrating fruit juices, flavors, and other food products without losing essential nutrients or aromas.

- Nutraceuticals & Herbal Extracts: Excellent for processing plant extracts, essential oils, and other materials sensitive to high temperatures.

- Biofuels & Renewable Energy: Suitable for concentrating bio-based feedstock in the production of biodiesel, ethanol, and other renewable fuels.

- Waste Management: Effective in recovering solvents and managing wastewater by reducing volume and concentrating contaminants.

With such versatility, ATFEs not only maintain product integrity but also help optimize energy consumption. This efficiency translates directly into cost savings and environmental benefits, meeting global demands for sustainable industrial practices.

Benefits of ATFE Technology

Why Choose Agitated Thin Film Evaporators?

- High Evaporation Rates: The continuous agitation and thin film formation result in rapid heat transfer, allowing higher evaporation capacity.

- Short Residence Time: Minimizes thermal degradation, making ATFEs perfect for sensitive materials like pharmaceuticals and food products.

- Energy Efficiency: Optimized design helps reduce the energy load, offering a lower carbon footprint and operational savings.

- Compact Footprint: Vertical construction takes up minimal space, making it easier to integrate into existing production lines.

- Flexibility in Processing: Handles wide-ranging viscosities and fluid types, from low-viscosity liquids to highly viscous slurries.

- Minimal Maintenance: The rotating wiper system’s self-cleaning action reduces fouling, extending operating intervals and lowering maintenance costs.